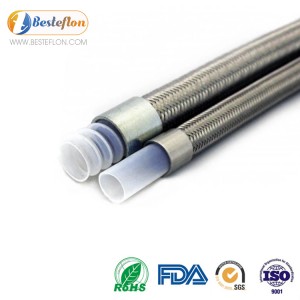

PTFE Corrugated Hose SS Braided Kink Resistance | BESTEFLON

Our Benefits:

Besteflon use advanced corrugated molding process, after a long time of use, not easy to produce cracks, safer use, longer life.

The objective in the pipeline design, the assembly can achieve the following purposes: absorbing vibration, suppressing the noise transmitted by rigid pipe, adapting to reciprocating and bending motion, and adjusting or correcting the micro-vibration. The pitch of the hose can be varied to meet the performance requirements rating in terms of flexibility and pressure.

The purpose of the stainless steel braid is to prevent elongation. The braided fabric is made of stainless steel wire, and the braiding tension is generated by the braiding pressure to provide radial and axial constraints. The multi-braided assembly adapts to higher pressures.

Bestflon brand PTFE Hose has data sizes ranging from 3 / 16 "to 2". Stainless steel braided PTFE bellows have a pressure range of up to 2944 psi, depending on size and operating conditions.

Special molding process produces less cracks

Besteflon uses advanced corrugated molding process, after a long time of use, not easy to produce cracks, with safer use, longer life.

Kink resistance and flexibility for easier hose handling

Stainless steel wire wrapped between the corrugations provides kink resistance while maintaining the flexibility required for hose handling.

Vacuum resistance at high temperature

The hose is vacuum resistant to - 0.9 bar at high temperatures. For more detailed information and to choose the best solution for your application, please contact our sales team.

PTFE Lined Fittings for Full Flow Media

Fittings (types: Camlock, Triclamp, Flange) can be lined with a PTFE layer to ensure adequate flow along the entire length of the hose assembly. Bushings mounted on the tubing eliminate fluid stagnation zones where particles of the conveyed media may accumulate. In addition, the liner can isolate the pipe material when chemically aggressive media is being delivered.

Inside wall

Medium wall, spiral-corrugated white/translucent PTFE

Braiding

Single stainless steel 304/316 wire braiding

Temperature range

From -65 to +260 ºC(-85°F---500°F)

Couplings

Press-fitted couplings in any design and material type

Characteristics

Corrosion resistance

Aging / oxidation / discoloration resistance

Suitable for pressure and vacuum

Suitable for high mechanical strength

Product Details

| Brand Name: |

BESTEFLON |

| Material: | 100% virgin PTFE + stainless steel wire |

| Specification: | 3/16'' to 2 '' |

| Thickness: | 0.85/1/1.2/1.5MM |

| Inside hose color: | milky white/translucent |

| Temperature range: | -65℃--+260℃ |

| Wire braided: | 304/316 stainless steel wire braided |

| Appliecation: | Chemical/Machinery equipment//Compressed gas/Fuel and lubricant handling/Steam transfer/ Hydraulic systems/Medical/Food/Pharmaceutical industry |

Convoluted Hose Range

| No. | Inner diameter | Outer diameter | Tube Wall Thickness |

Working pressure | Burst pressure | Minimum bending radius | Specification | sleeve size | ||||||

| (inch) | (mm±0.2) | (inch) | (mm±0.2) | (inch) | (mm±0.1) | (psi) | (bar) | (psi) | (bar) | (inch) | (mm) | |||

| ZXBW201-04 | 3/16" | 5.0 | 0.433 | 11.0 | 0.035 | 0.90 | 2944 | 203 | 8831 | 609 | 0.709 | 18 | -3 | ZX710-03 |

| ZXBW201-05 | 1/4" | 6.5 | 0.472 | 12.0 | 0.035 | 0.90 | 2489 | 172 | 7468 | 515 | 0.787 | 20 | -4 | ZX710-04 |

| ZXBW1201-06 | 5/16" | 8.0 | 0.516 | 13.1 | 0.035 | 0.90 | 2001 | 138 | 6003 | 414 | 0.906 | 23 | -5 | ZX710-05 |

| ZXBW201-08 | 3/8" | 10.0 | 0.610 | 15.5 | 0.035 | 0.90 | 1730 | 119 | 5191 | 358 | 0.984 | 25 | -6 | ZX710-06 |

| ZXBW201-10 | 1/2" | 13.0 | 0.756 | 19.2 | 0.035 | 0.90 | 1498 | 103 | 4495 | 310 | 1.102 | 28 | -8 | ZX710-08 |

| ZXBW201-12 | 5/8" | 16.0 | 0.906 | 23.0 | 0.035 | 0.90 | 1160 | 80 | 3480 | 240 | 1.969 | 50 | -10 | ZX710-10 |

| ZXBW201-14 | 3/4" | 19.0 | 1.055 | 26.8 | 0.035 | 0.90 | 1015 | 70 | 3045 | 210 | 2.480 | 63 | -12 | ZX710-12 |

| ZXBW201-16 | 7/8" | 22.2 | 1.181 | 30.0 | 0.039 | 1.00 | 923 | 64 | 2770 | 191 | 3.346 | 85 | -12 | ZX710-14 |

| ZXBW201-18 | 1" | 25.0 | 1.299 | 33.0 | 0.039 | 1.00 | 793 | 55 | 2378 | 164 | 3.543 | 90 | -16 | ZX710-16 |

| ZXBW201-20 | 1-1/8" | 28.0 | 1.398 | 35.5 | 0.039 | 1.00 | 575 | 40 | 1726 | 119 | 3.740 | 95 | -18 | ZX710-18 |

| ZXBW201-22 | 1-1/4" | 32.0 | 1.634 | 41.5 | 0.055 | 1.40 | 450 | 31 | 1349 | 93 | 3.937 | 100 | -20 | ZX710-20 |

| ZXBW201-26 | 1-1/2" | 38.0 | 1.890 | 48.0 | 0.059 | 1.50 | 392 | 27 | 1175 | 81 | 6.102 | 155 | -24 | ZX710-24 |

| ZXBW201-32 | 2" | 50.0 | 2.461 | 62.5 | 0.079 | 2.00 | 300 | 21 | 899 | 62 | 7.874 | 200 | -32 | ZX710-32 |

* Customer-specific products may be discussed with us for detailed.

Production workshop

How to cut the PTFE hose to avoid damaging the pipe?

In order to achieve the above purpose, the utility model provides the following technical scheme: a cutting device for the manufacture of polytetrafluoroethylene pipes, including a worktable, the upper surface of the worktable is provided with a bracket, the center of the lower surface of the support is fixedly connected with a hydraulic cylinder, the output shaft of the hydraulic cylinder is fixedly connected with a cutter, and the center of the upper surface of the worktable is provided with a first groove The first groove is located directly below the cutter, one side of the first groove is provided with a second groove, the second groove is provided with a first plate body, the outer wall of the first plate body is uniformly installed with a first slide block, the first sliding block slides in the second groove, one side of the first plate body away from the first groove is fixedly connected with a rocker The front surface of the worktable is provided with a third groove, the rocker is located in the third groove, the first groove is provided with a limit plate, one side of the limit plate far away from the first groove is fixedly connected with a bearing, the back surface of the worktable is provided with a threaded through hole, and the screw rod is connected with the thread in the threaded through hole.cut the PTFE hose

We offer the usual packing as follows

1、Nylon bag or poly bag

2、Carton box

3、Plastic pallet or plywood pallet

Customized Packaging is charged

1、Wooden reel

2、Wooden case

3、Other customized packaging also available